Effectively protecting yourself on a motorcycle is essential. We have come a long way since the 1970s, when Dainese created the first back protector. Protectors are now an integral part of every rider’s essential gear, but choosing random products is not enough. Products need to be certified by a certifying body that can confirm their protective qualities and ensure they meet the minimum requirements set out by Regulation (EU) 2016/425.

The UNI EN1621 standard is a set of general regulations that all protectors must meet. It is subdivided into sections that focus on different parts of the body. To obtain certification, products must pass strict laboratory tests that guarantee their level of protectiveness in order to earn a “quality stamp”.

Protectors can be certified on their own, by applying sections of the EN1621 standard, or together with the garment of which they are part, in which case standard EN 17092:2020 is used. In this case, and depending on the area of the body covered by the protector, the standard refers to the relevant part of EN1621. The primary purpose is clear – to ensure that the protective element does not move from the area to be protected in the event of a rider fall or accident.

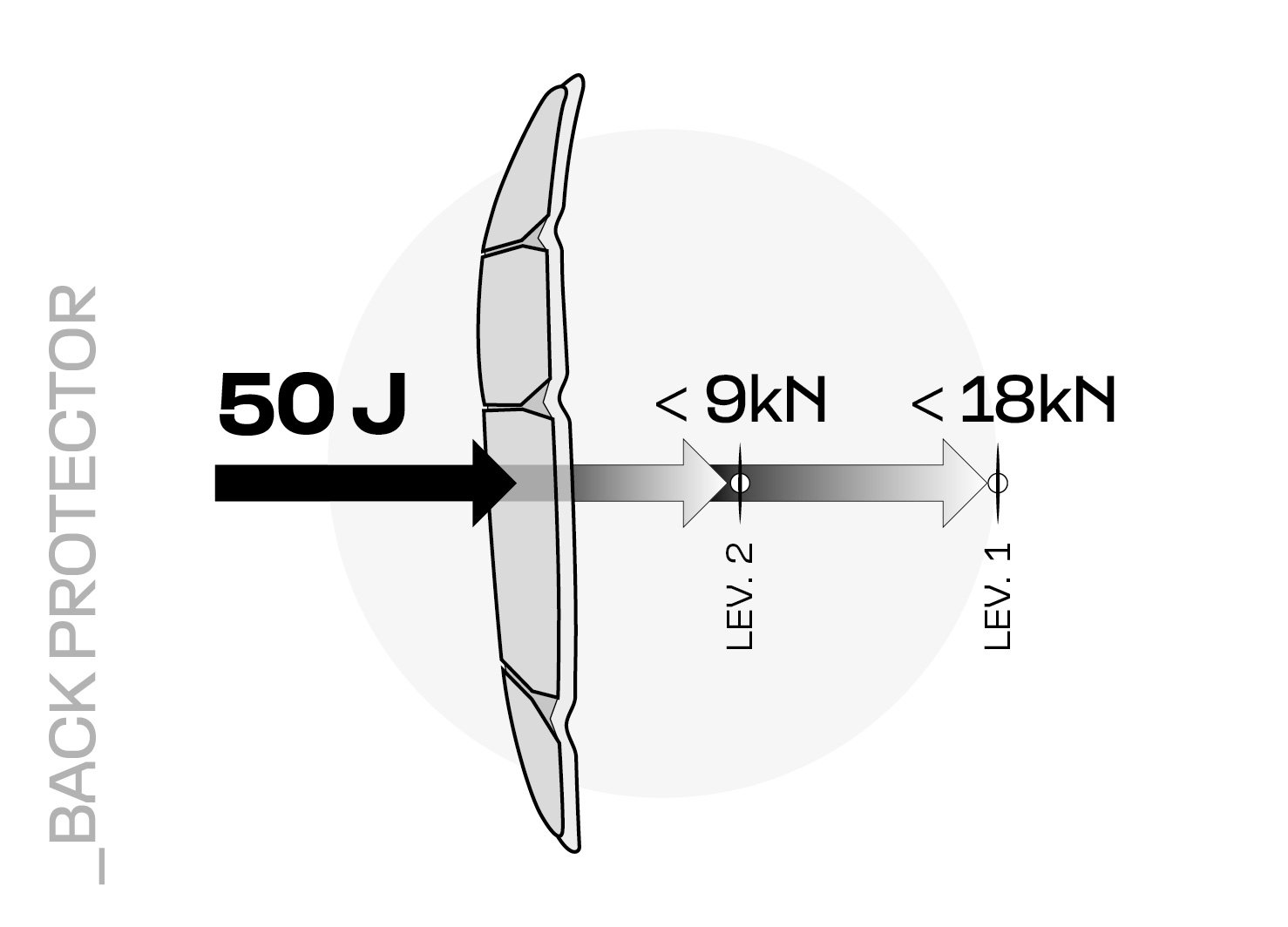

Certified back protectors, which are as indispensable as a helmet when riding, comply with the requirements included in section 2 of the applicable standard, specifically the UNI EN1621/2. To ascertain its effectiveness, a back protector is subjected to several impact tests involving a sharpened curbstone-like impactor, to simulate the kind of accident where a rider’s back impacts against a pointed surface (the curbside, for example), while wearing a back protector.

The force transmitted to the back determines the back protector’s classification. During a series of impact tests involving an impact energy of 50 J, a Level 1 device should transmit an average force of no more than 18 kN, with no single impact value greater than 24 kN. A Level 2 back protector, on the other hand – the best and most protective – should transmit an average force of no more than 9 kN, with no single impact value greater than 12 kN.

The CE symbol applied to the back protector shows the safety level, as well as the extent of the protected area, such as CB (central back) or FB (full back). The demarcation lines of the covered areas are drawn on a horizontal basis: A center back protector will protect the spinal column, while a full back protector extends to the sides, to include the shoulder blades.

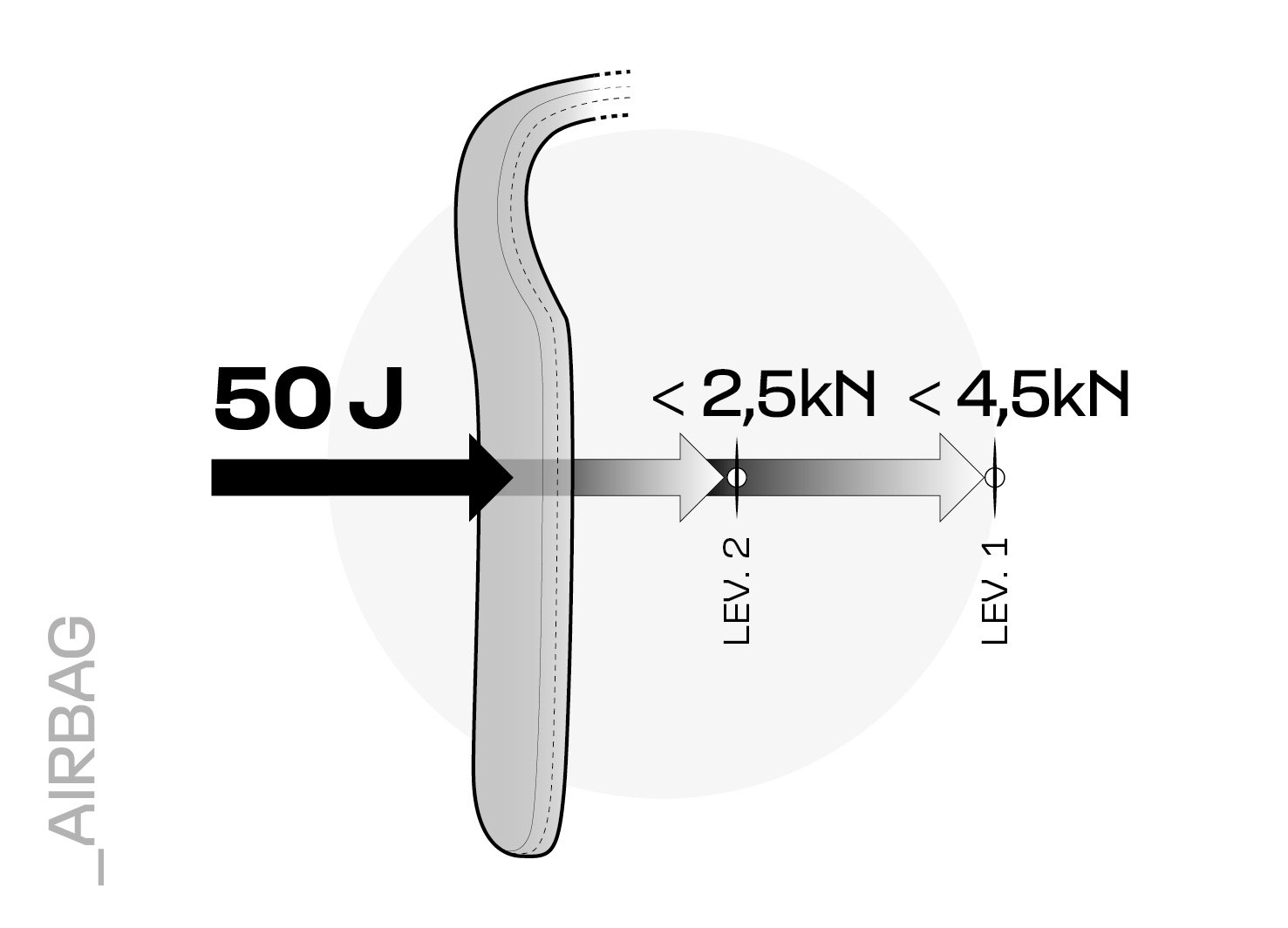

As far as airbag protection is concerned, the current European technical standard only regulates “mechanically activated” airbags, with EN1621.4. Electronically activated Dainese D-air® systems are so advanced and innovative that they go well beyond the limits set by this standard. Dainese and the external certifying body therefore needed to fill this regulatory void in order to offer clear indication of the protective standard of D-air® devices. This has given rise to a specific regulation, which adopts the standards required by EN1621/4 (mechanical airbags) as a reference.

The certification procedure includes a series of impact tests carried out on the Dainese D-air® airbag in accordance with 1621/4 standards. For Level 1, the threshold of force transmitted to the body cannot exceed 4.5 kN, while for Level 2 it cannot exceed 2.5 kN.

This is a way to bridge a gap in regulations that do not yet include certification for electronically-activated airbags, which are in fact the smartest and most advanced airbags, offering the highest level of safety.

On the market there are systems which use the expedient of an airbag with integrated hardshell protective gear. In fact, the 1621/4 standard allows for the possibility to certify the two protectors in combination, as the sum of the protective capacities of both. In this way, the qualities of a Level 2 back protector can be combined with a modest airbag to obtain, for example, a Level 1 certification according to 1621/4. But this does not clarify the protective performance of the airbag alone.

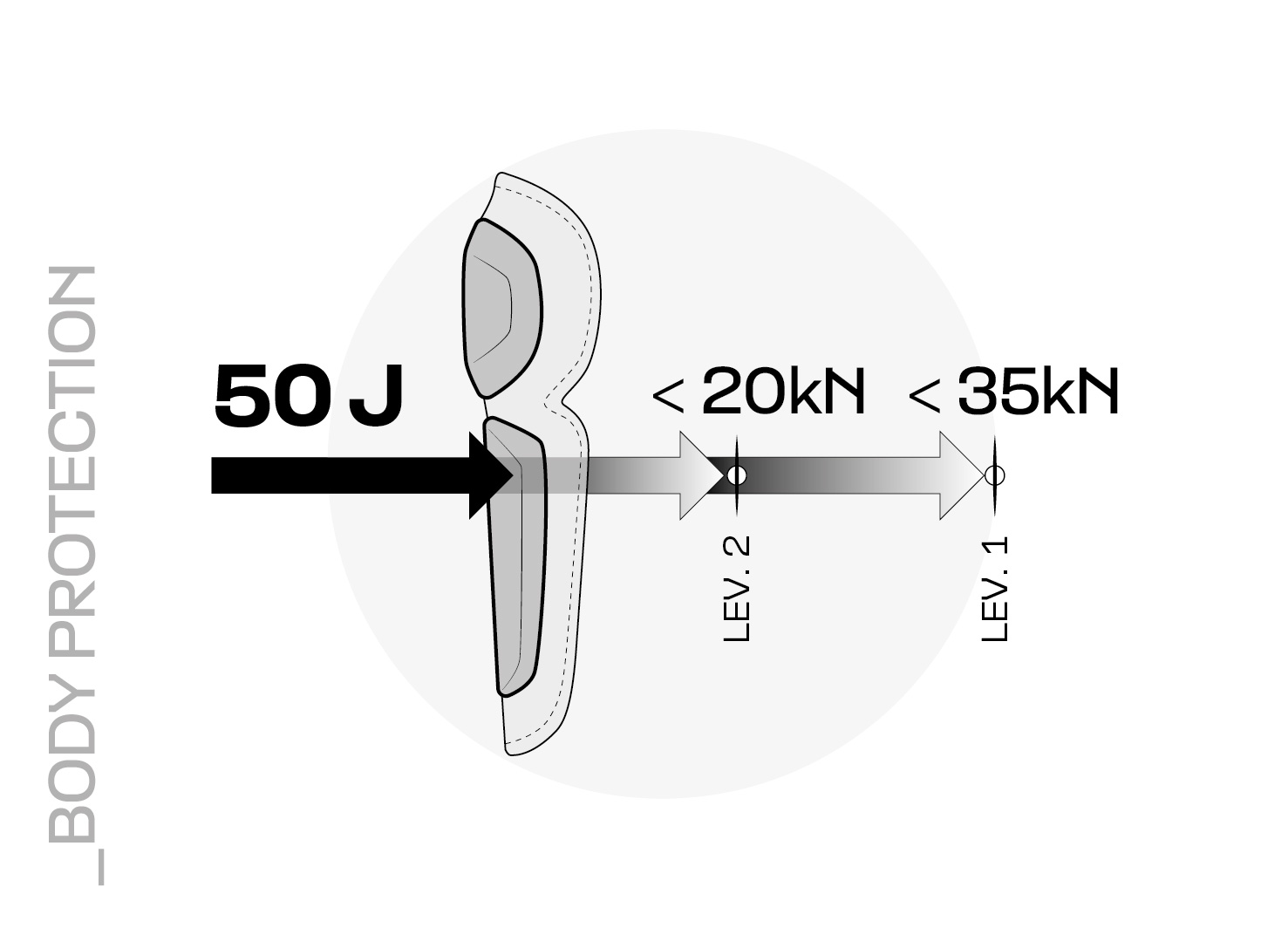

As for limb protectors (for example elbows, shoulders, knees and hips), their certification is governed by section 1 of the UNI EN1621 standard. In this case, protectors are made to withstand a longitudinal impact energy of 50 J (tested with a 5 kg anvil dropped from a 1 m height). For Level 1 protection, the average value of residual force affecting the body cannot exceed 35 kN, while for Level 2 protection this value cannot exceed 20 kN.

In light of what we just said, how important it is to be able to read product and limb protector labels is obvious – behind those seemingly unintelligible codes and numbers lies the key to a safe and well protected motorcycle ride.